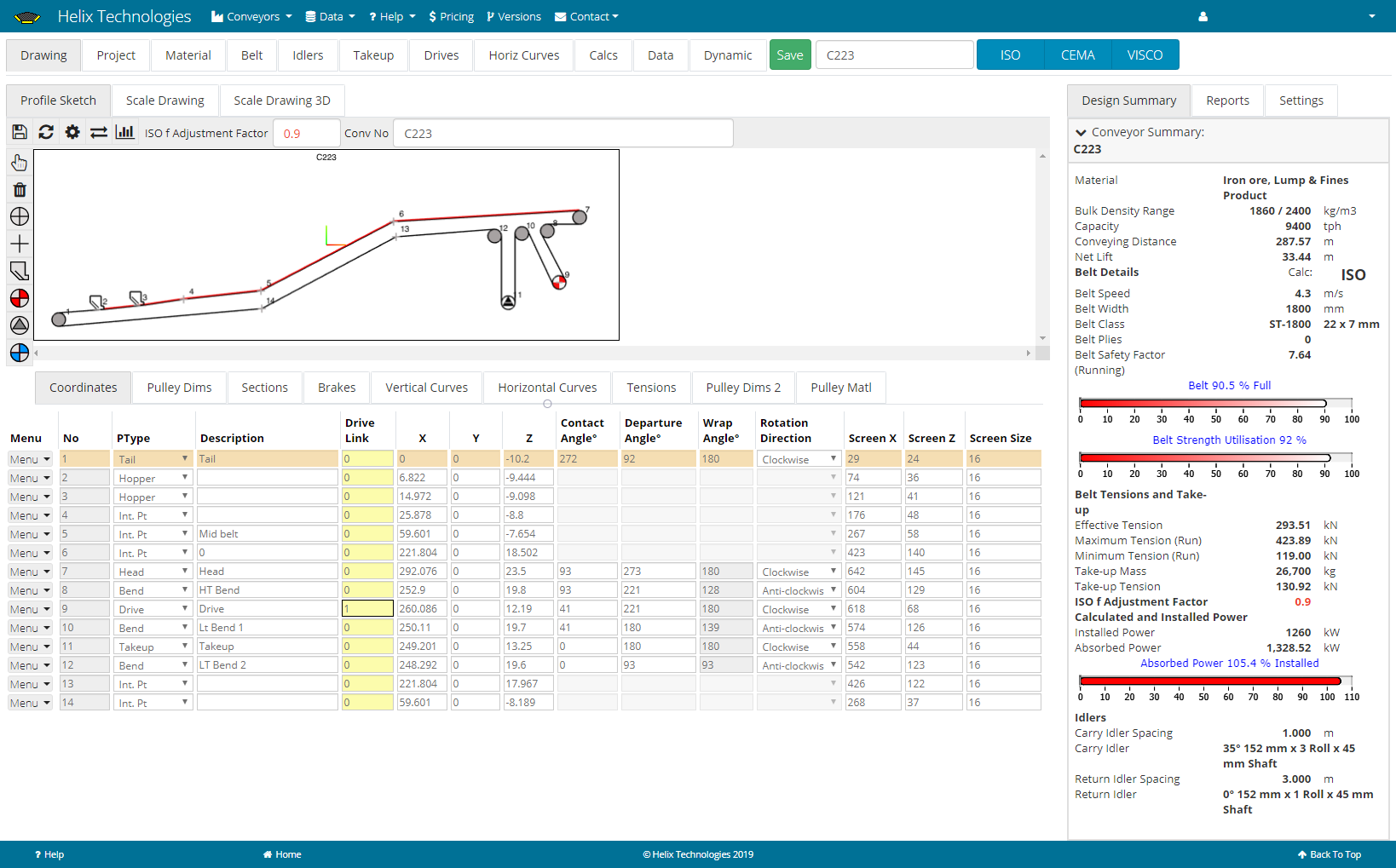

Go to the New Online version at helixconveyor.com

In 2020 we released a new online web based version of the existing Helix Delta-T6 desktop version that users had to manually install on their PC’s. It has been re-written with modern web development tools that have better features, is more user friendly and enables users to do all of their conveyor calculations in the web browser. Please go to helixconveyor.com , register and have a look at the new program. We recommend using Chrome or the new Edge (Chromium Edge released in 2020).

Some features of the new program:

- Online WebApp - No installation required

- Draw a sketch of the conveyor Profile and also view a scale drawing and a 3D line model of the conveyor

- Calculate using CEMA, ISO 5048 or the Viscoelastic method

- Tension and Power Calculations including graphs

- View and save pdf Reports

- Store all of your conveyors online

- Share conveyor files with other users

- Backwards compatible with the existing Helix DeltaT6 .xml conveyor files

- Purchase a yearly or monthly subscription and use the program immediately

Continue reading below for more details on the existing desktop version of the program.

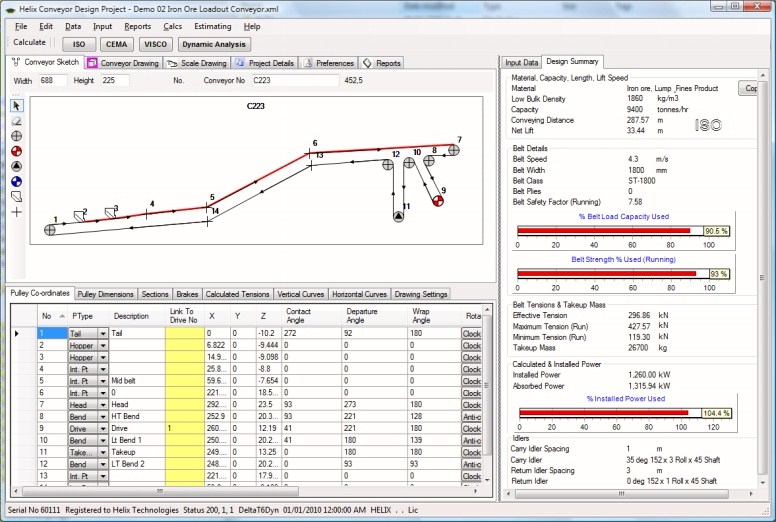

HELIX delta-T6 for Windows®

HELIX delta-T6 for Windows®

HELIX delta-T6 is a powerful computer software package developed to assist materials handling design engineers and equipment suppliers with conveyor design and optimisation. Helix Technologies' research and development of this software began in 1992 and delta-T now has more than a thousand users in 25 countries who depend on the program to provide consistent, accurate and cost effective belt conveyor and material handling designs. Features of the new delta-T version 6 program include:

- Automatic Selection of Belt and Tension, Power Calculations.

- Equipment Selection from Databases for Belts, Idlers, Pulleys & Shafts, Gearboxes, Motors, Fluid Couplings, Brakes etc.

- New Equipment databases for Shaft and Drive couplings and conveyor holdbacks have been added in version 6.

- Draw a sketch of the conveyor Profile and also view a scale drawing and a 3D model of the conveyor - use Drag and Drop to add Pulleys, Drives, loading Hoppers

- Calculate concave and convex Vertical Curves including belt lift off radii, edge tensions and centre tensions

- Horizontal Curve calculations - design curved conveyors including banking angle and belt drift calculations for all operating conditions

- Calculate using CEMA, ISO 5048 or the new Viscoelastic method for low resistance rubber belts

- Add any number of Conveyor Pulleys, Drives, Loading points, Trippers, Brakes etc

- Over 70 reports can be viewed, printed or exported to Word, PDF files or Excel etc.

- You can merge multiple selected reports into a single PDF file

- Delta-T6 has been completely re-written in Microsoft Visual Studio® and uses the latest software development tools from Microsoft. It is written in a development language called C# and uses the MS Common Language Runtime compiled for .Net with xml data. This technology is the latest available from Microsoft and this makes it compatible with the latest operating systems including Windows® XP, Vista® and Windows® 7, 8 and also 32bit and 64bit systems.

- Features in Helix delta-T6

Dynamic analysis module

Helix delta-T has a full flexible body conveyor dynamic analysis version.

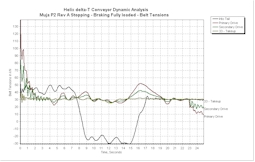

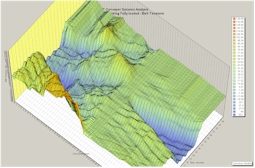

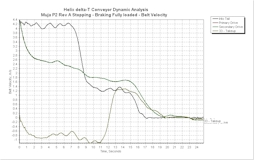

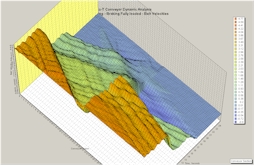

The Dynamic Analysis version calculates the transient belt Tensions and Velocities during starting and stopping of a conveyor. It can model the conveyor belt transient behaviour during Starting Fully Loaded, Starting Empty, Stopping Fully Loaded and Stopping Empty. The program allows the user to input any number of Drives or Brakes and allows for input of Drive Torque / Speed curves, Delay times, Braking Torques, Flywheels and inertia effects. After the Dynamic Calculations have been performed, the user can view and Print two dimensional and surface plot three dimensional graphs for Belt Tensions, Belt Velocities, Strain rates and Takeup movement versus time step for all points along the conveyor.

The following is a Helix delta-T6 sample Dynamic Analysis report - file size is 6Mb

Helix delta-T has been used as the design tool and proven in many hundreds of real conveyor installations in more than 25 countries around the world for more than 23 years. The latest version Helix delta-T 6 brings you even more power and flexibility in your conveyor designs.

The program will automatically calculate the belt tensions in the system, select a suitable belt from the database, calculate the pulley and shaft sizes required, select a suitable electric motor, fluid coupling and gearbox from the databases, calculate the idler shaft deflections and bearing life and then present the full conveyor design in reports which can be viewed, printed or exported to Word for Windows®, Excel®, PDF® files and other applications.

Belt tensions can be viewed graphically, and the Calc section provides useful procedures for calculating discharge trajectories, hoper pull-out forces, vertical curve radii, horizontal curve banking angles and belt drift, trough transitions distances and other frequently performed routines. Context sensitive on screen Help will guide you through the operating procedures and provide the formulae used in the calculations.

You can also create and view a 3D model of the conveyor. The program also allows you to dynamically calculate vertical and Horizontal curve geometry for the conveyor. In addition, delta-T provides an in-depth analysis of conveyor belt tensions under different operating conditions such as running fully loaded, running empty, starting fully loaded, starting empty, braking fully loaded, braking empty and coasting. A new sketch facility allows users to sketch the conveyor profile and enter data in tabular format.

Dynamic analysis 2D and 3D graphs

| 2D Belt Tensions | 3D Belt Tensions |

|---|---|

|

|

| 2D Belt Velocities | 3D Belt Velocities |

|---|---|

|

|

View a Delta-T6 Conveyor Design Brochure- pdf

View a Dynamic Analysis Case Study - pdf

View a PDF file brochure on the Dynamic Analysis module - pdf